Our company boasts numerous achievements through years of producing ultra-high-pressure hydrogen equipment and piping. We are applying this technology to expand activities relating to a hydrogen fueling infrastructure.

Hydrogen fueling equipment for industrial vehicles

Fueling equipment with hydrogen produced using renewable energy

Fuel-cell forklifts can be refueled in approx. 3minutes.

Hydrogen is produced through electrolysis of water using electricity generated by solar panels.

We have installed this equipment in our high-pressure equipment engineering department and at the Chubu Centrair International Airport. We offer tours primarily for customers interested in adopting the equipment.

Hydrogen is produced through electrolysis of water using electricity generated by solar panels.

We have installed this equipment in our high-pressure equipment engineering department and at the Chubu Centrair International Airport. We offer tours primarily for customers interested in adopting the equipment.

[Chubu Centrair International Airport - Equipment Specifications]

- Solar power generation system:CIGS solar cells (185W X 284panels:Approx.50kW)

- Hydrogen generator:polymer electrolyte pure water type (Max.5 N㎥/h)

- Hydrogen compressor:4-stage reciprocating compressor with normal pressure of 45 MPa

- Hydrogen storage unit:Four 300 L Type 3 composite vessels (normal pressure 45 MPa)

- Dispenser:35 MPa fueling (non precooling)

- Amount of hydrogen produced by renewable energy:Approx.40 N㎥/day

[Our high pressure equipment division - Equipment specifications]

- Solar power generation system:CIGS solar cells (160W X 324 panels:Approx.50kW)

- Hydrogen generator:polymer electrolyte pure water type (Max.5 N㎥/h)

- Hydrogen booster:90N㎥/day processed at normal pressure of 45 MPa

- Hydrogen storage unit:Two 300L Type3 composite vessels (normal pressure 45MPa)

- Dispenser:35 MPa fueling (non precooling)

MOVIE

Hydrogen fueling unit (1min. 35sec.)BELL Station mini (simple hydrogen refueling system)

This equipment fills up fuel cell forklifts with hydrogen.

Since it uses conventional gas filling equipment like compressed gas cylinders and curdles, it doesn't require a compressor or storage unit. This allows fueling equipment to be adopted for 1/10 the cost of regular fueling equipment.

Available in two specifications:Max. fueling pressure of approx. 19MPa or approx. 35MPa.

Since it uses conventional gas filling equipment like compressed gas cylinders and curdles, it doesn't require a compressor or storage unit. This allows fueling equipment to be adopted for 1/10 the cost of regular fueling equipment.

Available in two specifications:Max. fueling pressure of approx. 19MPa or approx. 35MPa.

MOVIE

Simple hydrogen refueling systemEquipment manufacture/construction technology

Storage unit manufacture

This vessel stores hydrogen for fueling fuel cell vehicles at hydrogen stations.

The vessel can hold 82MPa of hydrogen.

The vessel can hold 82MPa of hydrogen.

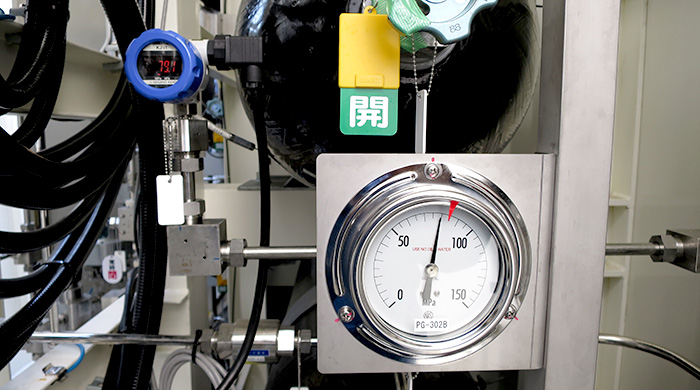

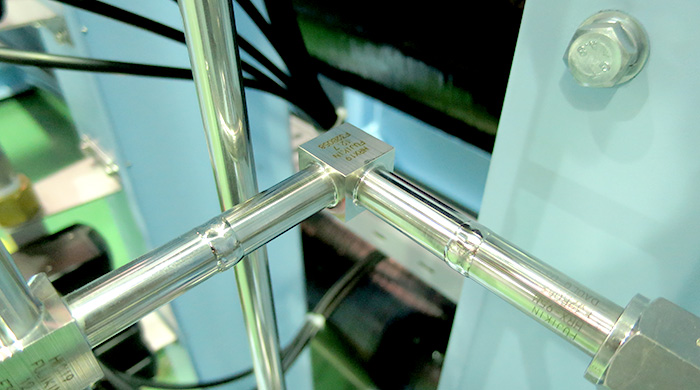

Piping construction

Coned and Threaded Connection Construction

We use a threaded piping connection type known as coned and threaded connections.

These can be used at a pressure of 99MPa.

These can be used at a pressure of 99MPa.

Welded construction

Welding is employed to ensure that there is zero leakage from connections.

These can be used at a pressure of 95MPa.

Piping walls can be made thinner than with coned and threaded connections. Therefore, piping can be made smaller while maintaining the same internal diameter.

Fittings such as valves can also be made smaller, allowing piping to be lighter and more compact.

These can be used at a pressure of 95MPa.

Piping walls can be made thinner than with coned and threaded connections. Therefore, piping can be made smaller while maintaining the same internal diameter.

Fittings such as valves can also be made smaller, allowing piping to be lighter and more compact.

Hydrogen station related construction

Commercial hydrogen station

We design and manufacture hydrogen storage units and hydrogen receiving frames for commercial hydrogen stations. We also carry out on-site installation work.

The photos show a fuel cell vehicle (FCV) owned by our company being filled with hydrogen at a commercial hydrogen station. Filling a fuel cell vehicle (FCV) with hydrogen entails sending hydrogen stored in the storage through fueling equipment referred to as a dispenser.

The photos show a fuel cell vehicle (FCV) owned by our company being filled with hydrogen at a commercial hydrogen station. Filling a fuel cell vehicle (FCV) with hydrogen entails sending hydrogen stored in the storage through fueling equipment referred to as a dispenser.

Demonstration hydrogen station

We were responsible for manufacture and on-site installation of the hydrogen storage unit and high-pressure hydrogen piping construction for the Shikaoi Hydrogen Farm in the Tokachi region of Hokkaido. We used welded construction for the piping.

Photo courtesy:NIPPON STEEL Pipeline & Engineering Co. Ltd.

Photo courtesy:NIPPON STEEL Pipeline & Engineering Co. Ltd.

Promotional video

Video

Suzuki Shokan's Hydrogen Business (5mins 40secs)